Create a Receipt

In Beta

This feature is currently in beta for select Procore customers.

This feature is currently in beta for select Procore customers.

You can use Procore to manage materials for your project. From the Materials tool, you can create receipts to track the materials you have received. You can create receipts for orders you placed outside of Procore, or from approved purchase and changed orders made in Procore's Commitments tool.

For customers using Commitments, it's recommended that you create a receipt from an order or a shipment. If you create a receipt from an order, it will automatically create a shipment. If you have already created a shipment for that order, it will create a duplicate. You can .

If creating a receipt from a shipment, the Document Status for the shipment must say 'Released'. See .

If creating a receipt from uploaded materials, you must create your receipt from the 'Create' button.

Locations must already be created in Procore. See Add Locations to a Project.

Materials must be listed in your inventory using one of the following methods:

The Commitments tool was used to create a purchase order or change order for materials, and includes the following information:

The status is Approved

The Schedule of Values (SOV) includes the following for each line item:

Description

Unit of Measure (UOM)

Create a receipt from the 'Create' button

Create a receipt from an order

Create a receipt from a shipment

If you uploaded your materials instead of ordering them through the Commitments tool, use this method to create your receipt.

Navigate to the project's Materials tool.

Add materials that need to be adjusted to your list. See .

Click Create and select Receipt.

Enter the 'Vendor' information.

Enter the 'Receipt Date'.

Select the 'Reference Type' for the receipt.

Enter the 'Reference Number' for the receipt.

Select the 'Inspected By Name' for the person who inspected the received materials.

Select the 'Received By Name' for the person who received the materials.

Optional: Enter any notes.

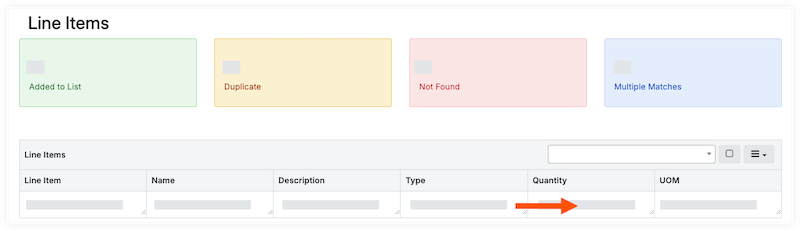

Under 'Line Items', click the quantity field for each line item and enter the quantity of the material that needs adjustment.

Click Build Document.

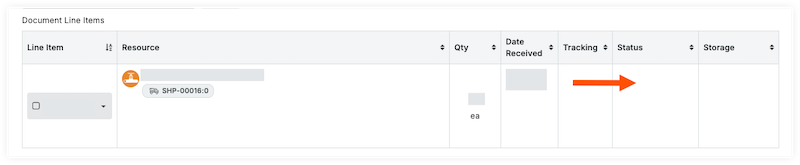

Under 'Document Line Items', review the line items.

Review the date received. If you need to make a change, see .

Review the quantity.

Enter the storage location for each line item.

Update an Individual Line Item

Click the To Location and select the location from the drop-down menu.

Click the From Location field and select the location from the drop-down menu.

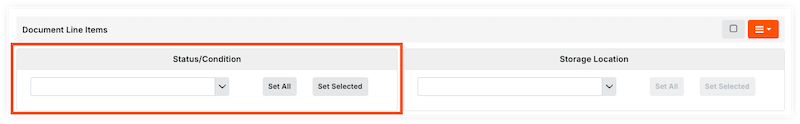

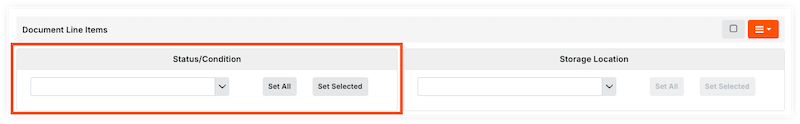

Bulk Update Line Items

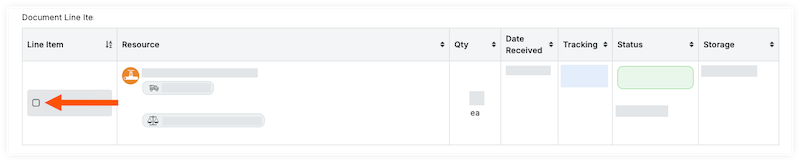

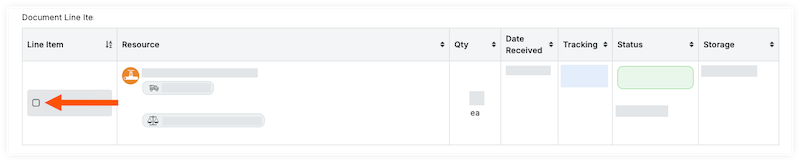

Mark the checkbox for each line item.

Under 'Storage Location', select the To Location or From Location from the drop-down menu.

Click Set Selected to set the location for the selected items or click Set All to set the location for all line items.

Add Materials to a Container

Follow steps to .

If materials received are unacceptable, over, short, or damaged (UOSD), follow the steps to .

Update the Status of acceptable materials.

Update an Individual Line Item

Click the 'Status' field for the item, and select the Checked > Acceptable from the drop-down menu.

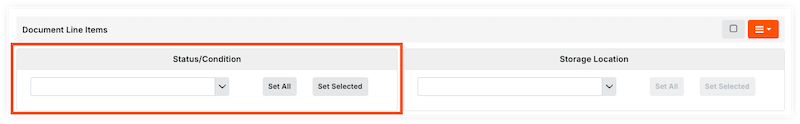

Bulk Update Items

Mark the checkbox for each line item.

Under 'Status/Condition', select the Checked > Acceptable from the drop-down menu.

Click Set Selected to set the status for the selected items or Set All to set the status for all line items.

If a line item is a replacement for a defect, follow steps to .

Optional: .

If you have already created a shipment, create the receipt from that shipment. Otherwise, you will create a duplicate shipment.

Navigate to the project's Materials tool.

Click the Control tab.

Click the Orders sub tab.

Click the order number you want to create a receipt for.

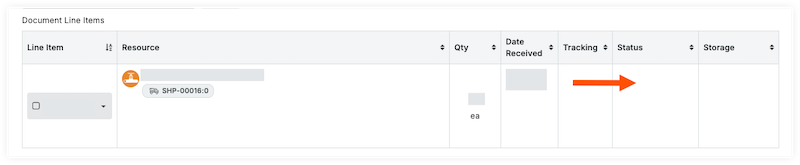

Mark the checkboxes for the items on the receipt.

OR

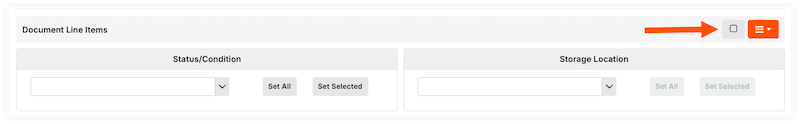

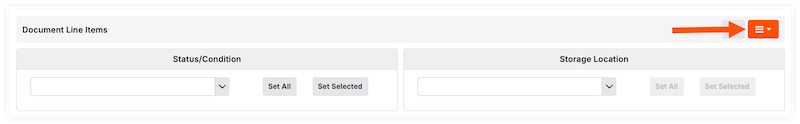

Select the checkbox in the 'Document Line Items' header to select all items on the order.

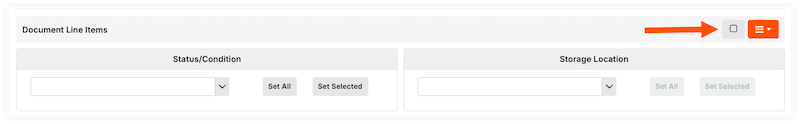

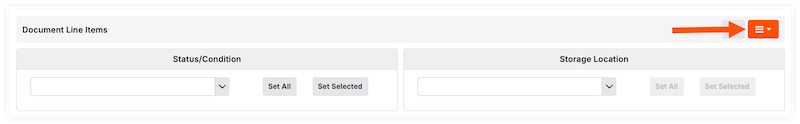

In the 'Documents Line Items' header, click the hamburger ![]() icon and select Create Receipt.

icon and select Create Receipt.

Enter the receipt information.

Click Create.

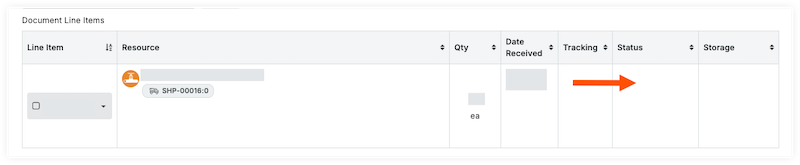

Under 'Document Line Items', review the line items.

Review the date received. If you need to make a change, see .

Review the quantity.

Enter the storage location for each line item.

Update an Individual Line Item

Click the To Location and select the location from the drop-down menu.

Click the From Location field and select the location from the drop-down menu.

Bulk Update Line Items

Mark the checkbox for each line item.

Under 'Storage Location', select the To Location or From Location from the drop-down menu.

Click Set Selected to set the location for the selected items or click Set All to set the location for all line items.

Add Materials to a Container

Follow steps to .

If materials received are unacceptable, over, short, or damaged (UOSD), follow the steps to Create a UOSD Defect.

If materials listed on the receipt are arriving in a separate shipment, click the 'Status' field for the item, and select the Zero Shipped.

Note: This will update the quantity of this line item to 0.

Update the Status of acceptable materials.

Update an Individual Line Item

Click the 'Status' field for the item, and select the Checked > Acceptable from the drop-down menu.

Bulk Update Items

Mark the checkbox for each line item.

Under 'Status/Condition', select the Checked > Acceptable from the drop-down menu.

Click Set Selected to set the status for the selected items or Set All to set the status for all line items.

If a line item is a replacement for a defect, follow steps to .

Optional: .

Navigate to the project's Materials tool.

Click the Control tab.

Click the Shipments sub tab.

Click the shipment you want to create a receipt for.

Mark the checkboxes for the items on the receipt

OR

Select the checkbox in the 'Document Line Items' header to select all items on the order.

In the 'Documents Line Items' header, click the hamburger ![]() icon and select Receive.

icon and select Receive.

Enter the receipt information.

Click Create.

Under 'Document Line Items', review the line items.

Review the date received. If you need to make a change, see .

Review the quantity.

Enter the storage location for each line item

Update an Individual Line Item

Click the To Location and select the location from the drop-down menu.

Click the From Location field and select the location from the drop-down menu.

Bulk Update Line Items

Mark the checkbox for each line item.

Under 'Storage Location', select the To Location or From Location from the drop-down menu.

Click Set Selected to set the location for the selected items or click Set All to set the location for all line items.

Add Materials to a Container

Follow steps to .

If materials received are incorrect, damaged, over, or short, follow the steps to .

If materials listed on the receipt are arriving in a separate shipment, click the 'Status' field for the item, and select the Zero Shipped.

Note: This will update the quantity of this line item to 0.

Update the Status of acceptable materials.

Update an Individual Line Item

Click the 'Status' field for the item, and select the Checked > Acceptable from the drop-down menu.

Bulk Update Items

Mark the checkbox for each line item.

Under 'Status/Condition', select the Checked > Acceptable from the drop-down menu.

Click Set Selected to set the status for the selected items or Set All to set the status for all line items.

If a line item is a replacement for a defect, follow steps to .

Optional: .