Optional: Create a UOSD Defect

In Beta

This feature is currently in beta for select Procore customers.

This feature is currently in beta for select Procore customers.

When you receive a shipment, check the materials to ensure all items are acceptable. Occasionally, you may receive materials that are unacceptable, over, short, or damaged (UOSD). If you find issues with the shipment, you can create a defect to track the issue, and resolve it with your vendor.

You can create a defect using the following statuses:

Damaged

Overage

Short

Unacceptable Note: This is typically used if the incorrect item was sent.

For overages and shorts, the parent receipt line quantity is updated, but the shipment quantity is kept the same. In other scenarios, the shipment quantity is automatically updated to match the receipt quantity when the receipt is posted.

After the receipt is posted, the UOSD ticket is automatically created after the receipt is posted. See .

Navigate to the project's Materials tool.

Click the Control tab.

Click the Receipts sub tab.

Click the receipt number.

Set the storage locations for all items before creating the UOSD/Defect for a line item. The defect line(s) will default to the same storage location. See .

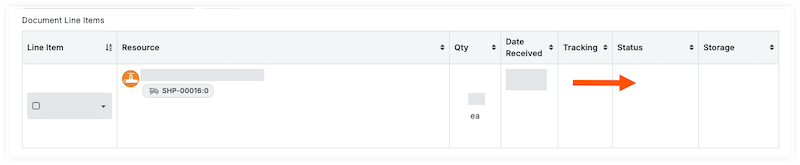

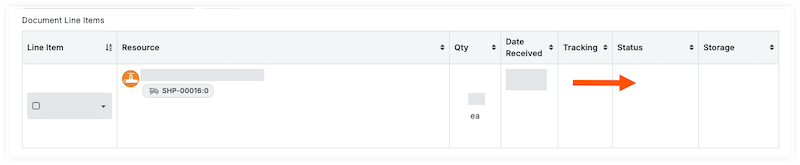

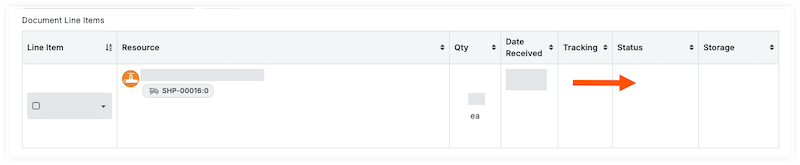

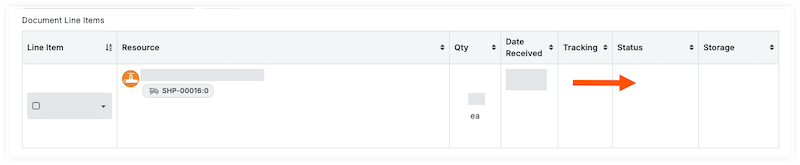

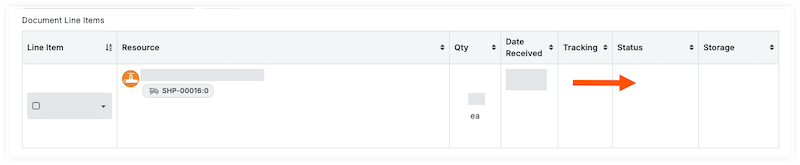

For the materials line item, click the 'Status' field and select Checked > Damaged.

This action creates two sub lines, one for the damaged materials (#.2) and one for acceptable materials (#.1). If you have multiple kinds of defects, you can add more sub lines to accurately track the quantity and status.

In the sub line #.2, complete the following information for the damaged materials:

Enter the quantity of the damaged materials.

Enter the location where the damaged materials are stored.

Optional: Enter notes.

Click Save.

For the remaining materials, review and enter information in sub line #.1.

Enter the quantity of materials.

Select the 'Status/Condition'.

Enter the location where the materials are stored.

Optional: Enter notes.

Optional: Attach photos by following these steps:

Click the caret icon for the line item and select Photo/Docs.

Do one of the following:

Click Add Files and select a file.

Drag and drop files in the attachments modal.

Click Upload.

Click Save.

Optional: To create additional sub lines, click the add sub line icon. Enter the information for the sub lines, and click Save.

Click sub line #.1 before adding additional sub lines to ensure the quantity of the new UOSD Defect is split from the acceptable quantity. New sub lines will take quantity from the selected sub line except when creating an overage.

Navigate to the project's Materials tool.

Click the Control tab.

Click the Receipts sub tab.

Click the receipt number.

Set the storage locations for all items before creating the UOSD/Defect for a line item. The defect line(s) will default to the same storage location. See .

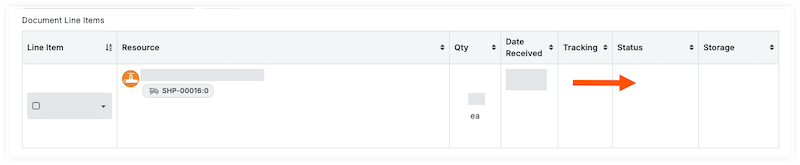

For the materials line item, click the 'Status' field and select Overage.

This action creates two sub lines, one for the overage quantity of materials (#.1.2) and one for acceptable materials (#.1.1). If you have multiple kinds of defects, you can add more sub lines to accurately track the quantity and status.

In the sub line 1.2, complete the following information for the extra materials:

Enter the quantity of the extra materials.

Enter the location where the extra materials are stored.

Enter notes.

Click Save.

For the remaining materials, enter the information in sub line 1.1.

Enter the quantity of materials.

Select the 'Status/Condition'.

Enter the location where the materials are stored.

Enter notes.

Click Save.

Navigate to the project's Materials tool.

Click the Control tab.

Click the Receipts sub tab.

Click the receipt number.

Set the storage locations for all items before creating the UOSD/Defect for a line item. The defect line(s) will default to the same storage location. See .

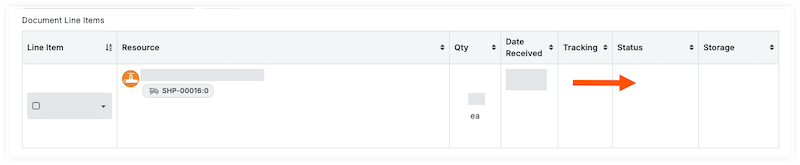

For the materials line item, click the 'Status' field and select Short.

This action creates two sub lines, one for the quantity short (#.1.2) and one for acceptable materials (#.1.1). If you have multiple kinds of defects, you can add more sub lines to accurately track the quantity and status.

In the sub line 1.2, complete the following information for the short materials:

Enter the quantity of materials that were expected, but not included in the shipment.

Enter notes.

Click Save.

For the remaining materials, enter the information in sub line 1.1. Note: The quantity automatically updates to the amount you received, taking into account the short quantity.

Select the 'Status/Condition'.

Enter the location where the materials are stored.

Enter notes.

Click Save.

Navigate to the project's Materials tool.

Click the Control tab.

Click the Receipts sub tab.

Click the receipt number.

Set the storage locations for all items before creating the UOSD/Defect for a line item. The defect line(s) will default to the same storage location. See .

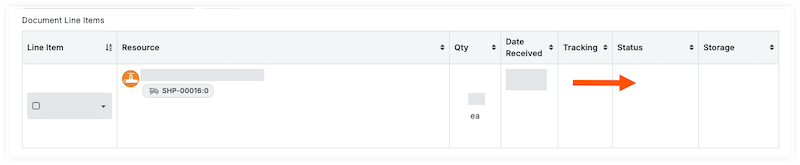

For the materials line item, click the 'Status' field and select Checked Unacceptable.

Enter the quantity of materials that are unacceptable.

Enter the location where the materials are stored.

Enter any notes.

Click Save.

Optional: To create additional sub lines, click the add sub line icon. Enter the information for the sub lines, and click Save.

Navigate to the project's Materials tool.

Click the Control tab.

Click the Receipts sub tab.

Click the receipt number.

Set the storage locations for all items before creating the UOSD/Defect for a line item. The defect line(s) will default to the same storage location. See .

For the materials line item, click the 'Status' field and select Checked > Damaged.

This action creates two sub lines, one for the damaged materials (#.2) and one for acceptable materials (#.1). If you have multiple kinds of defects, you can add more sub lines to accurately track the quantity and status.

In the sub line #.2, complete the following information for the damaged materials:

Enter the quantity of the damaged materials.

Enter the location where the damaged materials are stored.

Optional: Enter notes.

Click Save.

For the remaining materials, review and enter information in sub line #.1.

Enter the quantity of materials.

Select the 'Status/Condition'.

Enter the location where the materials are stored.

Optional: Enter notes.

Optional: Attach photos by following these steps:

Click the caret icon for the line item and select Photo/Docs.

Do one of the following:

Click Add Files and select a file.

Drag and drop files in the attachments modal.

Click Upload.

Click Save.

Optional: To create additional sub lines, click the add sub line icon. Enter the information for the sub lines, and click Save.

Click sub line #.1 before adding additional sub lines to ensure the quantity of the new UOSD Defect is split from the acceptable quantity. New sub lines will take quantity from the selected sub line except when creating an overage.

Navigate to the project's Materials tool.

Click the Control tab.

Click the Receipts sub tab.

Click the receipt number.

Set the storage locations for all items before creating the UOSD/Defect for a line item. The defect line(s) will default to the same storage location. See .

For the materials line item, click the 'Status' field and select Overage.

This action creates two sub lines, one for the overage quantity of materials (#.1.2) and one for acceptable materials (#.1.1). If you have multiple kinds of defects, you can add more sub lines to accurately track the quantity and status.

In the sub line 1.2, complete the following information for the extra materials:

Enter the quantity of the extra materials.

Enter the location where the extra materials are stored.

Enter notes.

Click Save.

For the remaining materials, enter the information in sub line 1.1.

Enter the quantity of materials.

Select the 'Status/Condition'.

Enter the location where the materials are stored.

Enter notes.

Click Save.

Navigate to the project's Materials tool.

Click the Control tab.

Click the Receipts sub tab.

Click the receipt number.

Set the storage locations for all items before creating the UOSD/Defect for a line item. The defect line(s) will default to the same storage location. See .

For the materials line item, click the 'Status' field and select Short.

This action creates two sub lines, one for the quantity short (#.1.2) and one for acceptable materials (#.1.1). If you have multiple kinds of defects, you can add more sub lines to accurately track the quantity and status.

In the sub line 1.2, complete the following information for the short materials:

Enter the quantity of materials that were expected, but not included in the shipment.

Enter notes.

Click Save.

For the remaining materials, enter the information in sub line 1.1. Note: The quantity automatically updates to the amount you received, taking into account the short quantity.

Select the 'Status/Condition'.

Enter the location where the materials are stored.

Enter notes.

Click Save.

Navigate to the project's Materials tool.

Click the Control tab.

Click the Receipts sub tab.

Click the receipt number.

Set the storage locations for all items before creating the UOSD/Defect for a line item. The defect line(s) will default to the same storage location. See .

For the materials line item, click the 'Status' field and select Checked Unacceptable.

Enter the quantity of materials that are unacceptable.

Enter the location where the materials are stored.

Enter any notes.

Click Save.

Optional: To create additional sub lines, click the add sub line icon. Enter the information for the sub lines, and click Save.